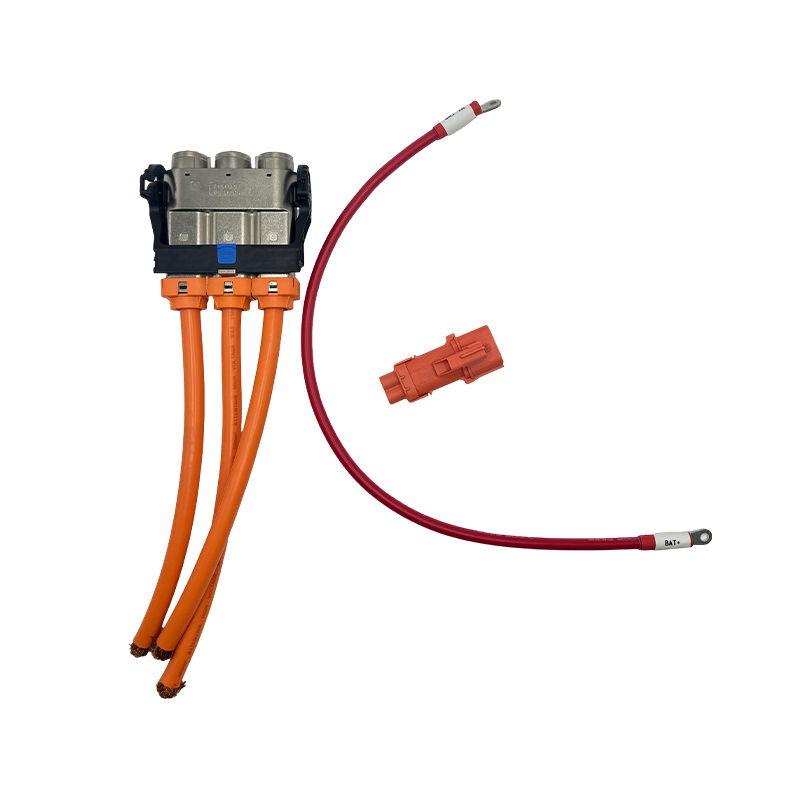

New Energy High Voltage Wiring Harness And Connector

New energy high-voltage wiring harnesses and connectors play a key role in electric vehicles (EVs) and other renewable energy systems. They are responsible for providing safe and reliable power transmission between high-voltage batteries, drive motors, charging systems and other electrical components.

1. Product Features

High-voltage wiring harness

High voltage carrying capacity:

Usually designed to carry high voltages above 600V, to meet the needs of electric vehicles and energy storage systems.

Multi-core design:

High-voltage wiring harnesses usually include multiple wires to support the connection of different electrical components and provide current and signal transmission.

Waterproof and dustproof:

Adopt IP67 or higher protection level to ensure stability and safety in harsh environments.

High temperature and corrosion resistance:

The material is resistant to high temperatures, adapts to the temperature range of -40°C to +125°C, and can resist the corrosion of chemical substances.

Lightweight design:

Use lightweight materials to reduce the overall weight of the vehicle and improve energy efficiency.

High-voltage connector

High current carrying capacity:

Designed to carry 100A to 300A or more, ensuring efficient energy transmission.

Safety locking mechanism:

Many high-voltage connectors are equipped with a locking mechanism to ensure the reliability of the connection and prevent loosening during use.

Simple connection method:

Provides quick connection and removal functions for easy installation and maintenance.

Good conductivity:

Conductors are usually made of highly conductive copper material, nickel-plated or gold-plated to enhance corrosion resistance.

2. Application scenarios

Electric vehicles (EV):

High-voltage wiring harnesses and connectors are used to connect battery packs, drive motors, and charging systems to ensure safe and efficient power transmission.

Energy storage system:

In solar energy storage and wind energy storage systems, they are used to connect batteries and inverters to support efficient energy management and conversion.

Industrial equipment:

In industrial electrical equipment and robots, they are used to connect high-voltage power supplies to provide stable power supply.

3. Installation and maintenance

Installation precautions:

Ensure that the installation of high-voltage wiring harnesses and connectors complies with the manufacturer's recommendations, avoid excessive bending and pulling, and prevent damage.

Regular inspection:

Regularly check the wear, corrosion, and aging of wiring harnesses and connectors to ensure safe operation.

Use protection measures:

For high-voltage connectors, it is recommended to use protective covers when not in use to prevent the intrusion of moisture and dust.

4. Summary

New energy high-voltage wiring harnesses and connectors play an important role in electric vehicles and energy storage systems to ensure efficient and safe power transmission. Their design takes into account the requirements of high voltage, high current and complex environment, providing important guarantees for the reliability and safety of modern electric transportation and renewable energy systems.

High-voltage wiring harness

Rated voltage: 600V or higher

Conductor material: usually copper

Insulation material: commonly used polyvinyl chloride (PVC), cross-linked polyethylene (XLPE), etc.

Operating temperature range: -40°C to +125°C

Protection level: IP67 or higher

High-voltage connector

Rated voltage: usually 600V or higher

Rated current: 100A to 300A

Connector type: various types, including plug-in type, locking type, etc.

Material: plastic shell (usually UL certified material), copper conductor